Supports up to 126 CANopen® Nodes with up to 14 RPDOs and TPDOs

- Up to 1440 bytes input and 1440 bytes output data possible

- Reliable data transmission even with high CAN bus load

Easy-to-configure Communication between PROFINET® and CANopen®.

- Automatic creation of configurations from EDS files

- Included configuration tool GSDML Composer for easy commissioning

Reliable Communication and advanced Functions for Diagnostics and Debugging

- User-friendly analysis of the CAN bus via the USB interface

- Extended error diagnostics of the CANopen® nodes directly in the PLC

- LEDs for easy reading of PROFINET® and CAN status

- Additional free software tools for CAN debugging (e.g.: CANreal)

This product is certified by PROFIBUS Nutzerorganisation e.V. (PNO).

esd electronics has been a member of the PROFIBUS user organisation e.V. (PNO) for many years.

Connection of PROFINET® IO and CANopen®

The CANopen-PN/2 connects any PROFINET® IO controller to a CANopen® network.

The fieldbus gateway operates as a PROFINET® IO device with a maximum of 1440 bytes of input data and 1440 bytes of output data and as a CANopen® manager with support for Network Management (NMT), Node Guarding and Heartbeat.

Application

The CANopen-PN/2 connects CANopen® modules with CANopen® modules (CiA 301) with e.g. a SIMATIC-S7. A maximum of 126 CANopen® nodes can be connected to the gateway.

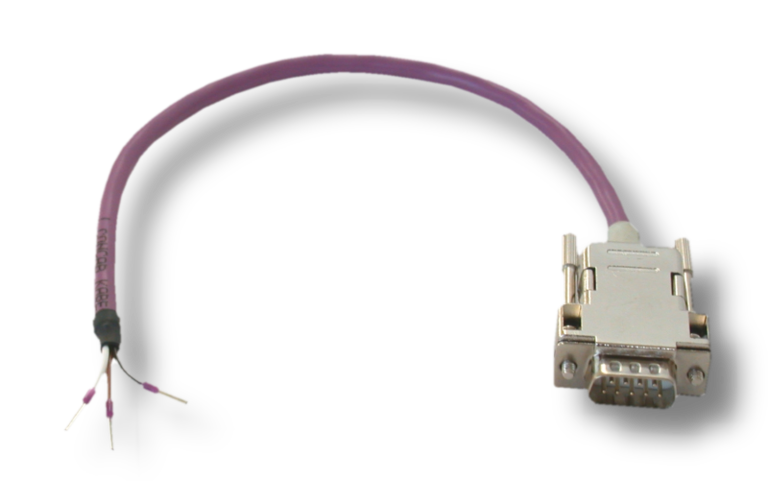

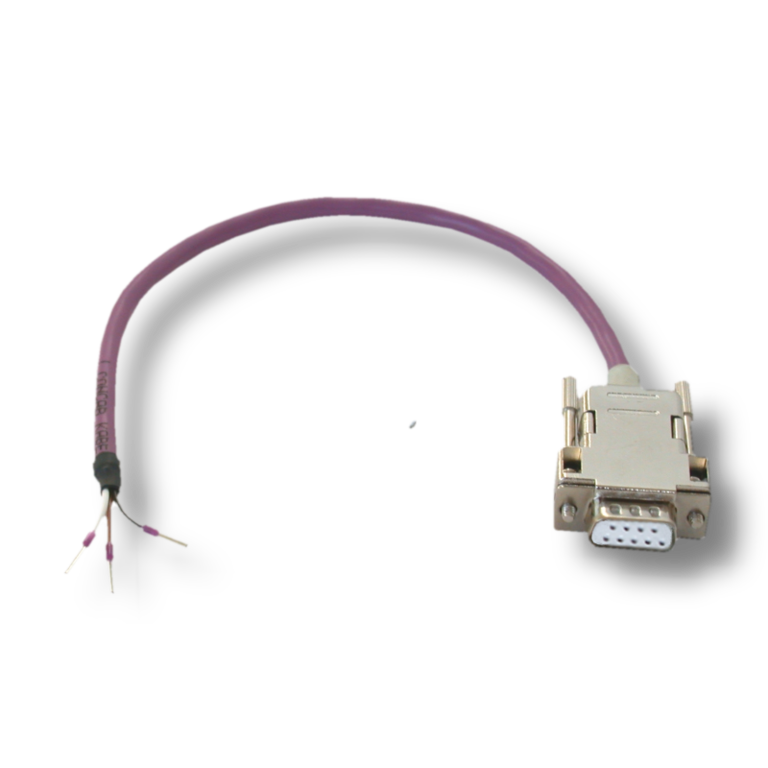

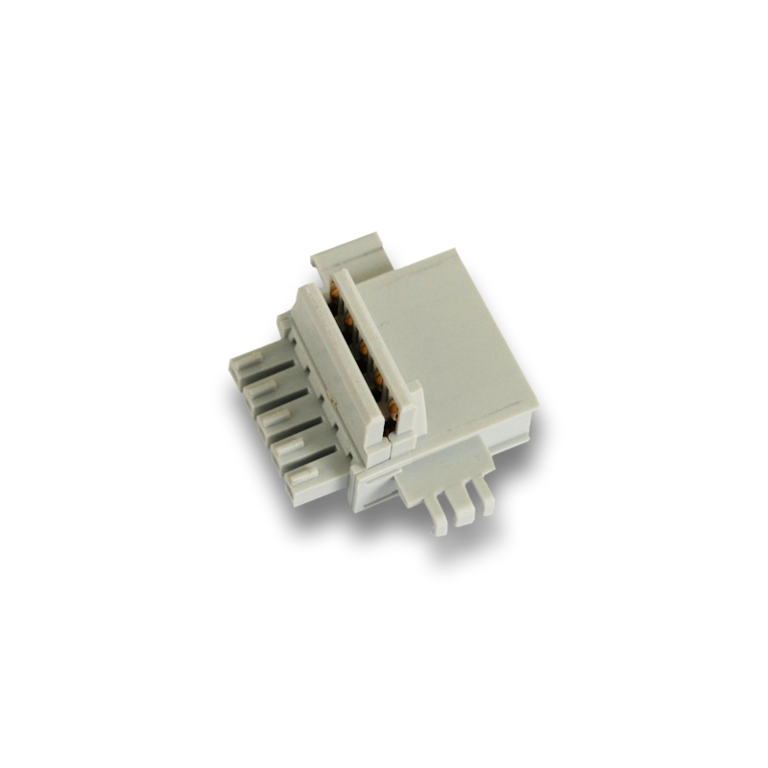

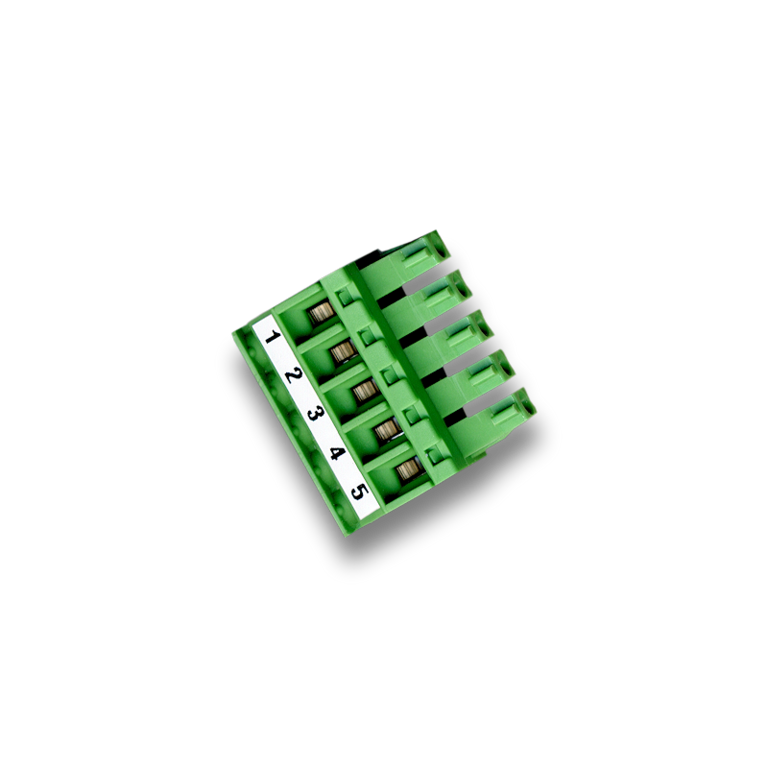

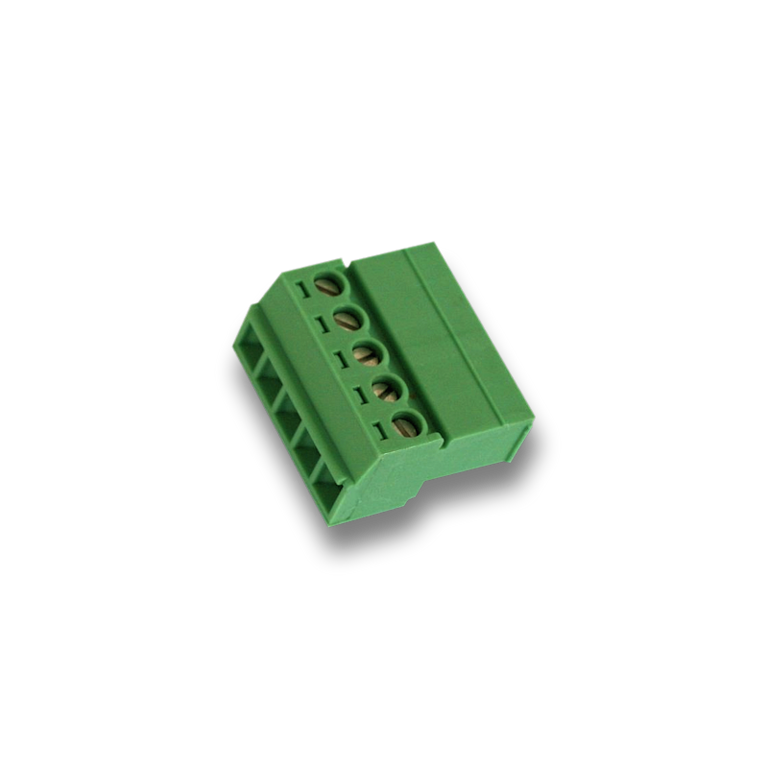

Physical Interfaces

The ISO 11898-2 compatible CAN interface allows a maximum data transmission rate of 10 kBit/s up to 1 MBit/s. The 100BASE-TX PROFINET® IO interface is compatible with IEEE802.3 and offers a data transmission rate of 100 MBit/s. Both the PROFINET® IO and CANopen® interfaces are galvanically isolated from the rest of the circuit.

Easy configuration and extensive debugging options

The module can be configured as a PROFINET® IO configuration tool via the GSDML Composer.

A live view of the CAN bus on a Windows PC is possible via the integrated USB interface with the free CANreal tool. This allows configuration errors to be found easily and quickly. In addition, it is possible to display the CAN statistics data on the utilization of the CAN bus in CANreal or directly in the PLC.

Do you have special requirements regarding the product?

We are happy to provide you with a customer-specific option or adjustment to our products when purchasing appropiate quantities. Please contact our sales team for detailed information.

With the help of the button "Add to watchlist" you can save articles on your watchlist.

Afterwards, you can request your saved watch list as a quotation via a contact form.

Hardware

High-performance PROFINET-IO-Device to CANopen Manager Gateway. CAN-Physical-Layer according to ISO-11898-2 and PROFINET-Physical -Layer 100BASE-TX according to IEEE802.3 with galvanic isolation on both sides. Compact housing for DIN rail mounting with easily accessible connectors. System integration using the esd GSDML composer for individual generation of the matching configuration. Extensive debugging with CAN diagnostic software (CANreal, CANplot and COBview) via USB interface.

- galvanically isolated

- CAN

- CANopen Manager

- PROFINET

- Linux

- Windows 7/8/10/11

- CAN-Layer 2

- CANopen

- PROFINET