Modular system design achieves good scalability for shearer loaders

CAN bus modules in mining heavy machinery

The company Eickhoff from Bochum stands for innovation in heavy mechanical engineering, whether it is for gearboxes for wind turbines or cast parts and shearer loaders for the mining industry.

Since the year 2000, the company has been using the CAN bus for the development and commissioning of shearer loaders. Since then, esd electronics has provided various CAN I/O modules and CAN interfaces for all the shearer loaders of the SL series reaching good scalability of the controller. Recent developments with EtherCAN/2 modules are intended to extend the remote diagnostic functionality down to the CAN level.

The development and production of components for underground mining at Eickhoff dates right back to the year 1914. The bar milling machine introduced to the market at that time was among the first complete Eickhoff systems. That is how the worldwide success story of Eickhoff's coal extraction machines began. Today, the product line ranges from the SL 300 L roller loader with a machine body of only 75 cm height and two 300 kW cutting motors for low seams from 1.2 to 1.8 meters up to the SL 1000 roller loader with an installed capacity of 2,800 kW and for seam thicknesses of up to 8.6 meters.

All machine series have a modular design and can be optimally adapted to the height of the seams and the existing infrastructure. For this purpose, only a few components need to be replaced. With its wide range of machines, customized adaptations and innovative automation solutions, Eickhoff continues to set new standards in the development of roller loaders regarding size, usability and efficiency.

Scalable Control

In the year 2000 the requirement of a modular control system soon guided the developers of Eickhoff to products from esd electronics. Arnold Schymonski from the BT-KE department at Eickhoff recalls "At that time we used the CAN interface “CAN-USB” with the CAN monitoring software "CANreal" for the development and commissioning of the roller loader.” Since 2002, Eickhoff has been using various CAN I/O modules from esd electronics, which today are used in all roller loaders of the SL series. The controller is based on an IPC with CAN and PROFIBUS as interfaces to the machine peripherals.

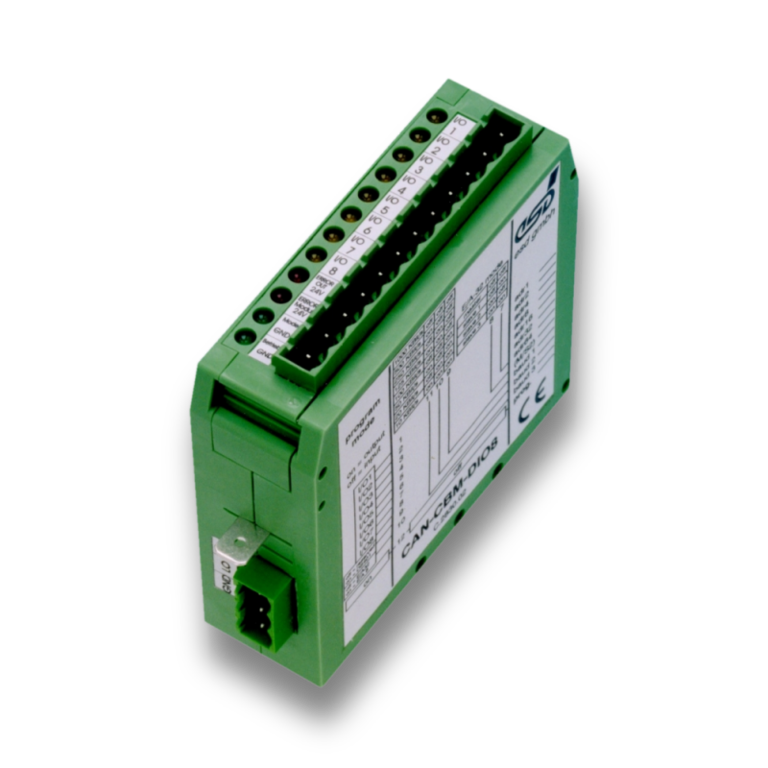

Using the CANopen modules CAN-CBM-AI410 and CAN-CBM-DIO8, analog and digital signals are read into the controller, such as switching signals from the control panel or measured values of supply voltages. Via the output modules CAN-CBM-DIO8 or CAN-CBM-REL4 the controller manages different aggregates or displays. "The modular system design offers the necessary flexibility to expand systems and to adapt them to current requirements or customer demands. This gives the controllers good scalability," explains Arnold Schymonski.

Harsh environmental Conditions

In mining, obeying regulations of explosion protection is mandatory. The electric switchboard of the roller loader with medium-voltage system, converter and controller is therefore included in the ignition protection type "Pressurized Encapsulation". The CANopen components are installed in the housing of the distribution. Due to the confined installation conditions and the proximity to medium-voltage switchgears as well as to frequency converters, special thermal and high EMC requirements are placed on the controller and the modules. In addition, the components are exposed to mechanical loads such as vibration and shock as well as to corrosive influences caused by the moisture of the mine water. To increase the electronics’ resilience to these kind of environmental influences protective measures are required. esd electronics therefore uses components with a higher temperature range for these assemblies (-40 °C to + 85 °C). Moreover, the printed circuit boards are protected by coatings and the components are glued for mechanical security.

Intelligent Automation

In order to handle the wide range of automation tasks Eickhoff uses soft PLCs based on CompactPCI-IPCs. The control software including the automation tasks have been programmed under CoDeSys (according to IEC 61131-3) by the technical department at Eickhoff. These solutions are known as EiControl and EiControlPlus and perform a whole range of automation tasks in roller loaders of various stages of expansion. Especially EiControlPlus stands for a completely autonomous extraction system allowing the service staff to operate from a safe area and no longer in harsh surroundings. The corresponding machines are equipped with a wide variety of sensors for “seeing”, “hearing” and “sensing”.

Outlook

In order to expand the remote diagnostic system of the machines, Eickhoff plans on using the EtherCAN/2 module to allow access down to the CAN level. The remote connection to the roller loader is then established via Ethernet. Arnold Schymonski reports "We are currently testing the feasibility of this extension and are gaining initial experience in use".

A further current project includes the operation of the second CAN interface of the CPCI-CAN/200-2TC module already in use. Since communication of the entire periphery currently runs via a single CAN bus, the drive control of the machines needs to be equipped with its own CAN bus. "We expect that this clear sharing will lead to a reduction of the bus load in both CAN strings. The stability and availability of the control system on the other hand can be further increased," Arnold Shymonsky explains.

Download the complete case study as PDF

-

Modular system design achieves good scalability for shearer loaders Complete user report as PDF 2 MB